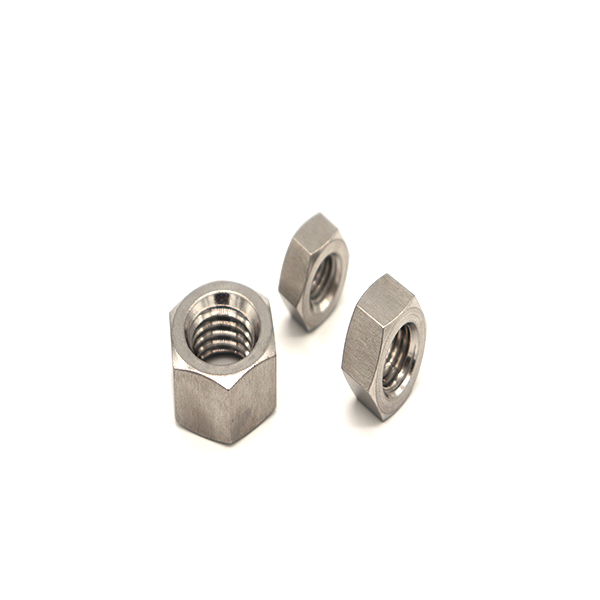

Inconel zeskantbout

- NEWSTARWDH

- CHINA

- 7-35 DAG

- 1000 TON

Productnaam: Inconel zeskantbouten

Materiaal: Inconel 600, Inconel 601, Inconel 625, Inconel 718, Inconel 725, Inconel X-750

Standard: ASME / ANSI B 18.2.1, IFI149, DIN931, DIN933, DIN960, DIN961, DIN558, ISO4014 , ISO4017, ISO8765, ISO8676, JIS B1180

Meetsysteem: INCH, Metrische

maat: 1/4 "-3", M5-M100

Draad: M, UNC, UNF

Uniform corrosion of inconel fasteners can occur in acidic or hot alkaline solutions. Through this mechanism, losses can be expected and allowed in the design. When the corrosion rate of inconel products is very slow, the metal is in a passive state, generally the corrosion resistance is better with a larger chromium content, but other solutes can be harmful.

Product Brief

The uniform corrosion of inconel products can occur in acidic or hot alkaline solutions. Through this mechanism, losses can be expected and allowed in the design. When the corrosion rate of inconel products is very slow, the metal is in a passive state, generally the corrosion resistance is better with a larger chromium content, but other solutes can be harmful.

Inconel steel products in the chemical composition near the grain boundary can be changed by the recipeof chromium-rich particles. The resulting chromium-depleted zone at the grain boundary makes the 4cr13 stainless steel tube product vulnerable to intergranular anode attack, even under stress-free conditions.

Designation of inconel steel products means that 12% Cr content exceeds a little. Most stainless steels are based on Fe-Cr-C and Fe-Cr-Ni-C systems, but are also important other alloying elements.

Inconel steel products can be in several crystal forms, the most common of which is the presence of body-centered cubic (bcc) and face-centered cubic (fcc). In pure iron, the fcc structure still exists between 910 and 1400 ° C, and the body-centered cubic structure below and above this time interval (up to a melting temperature of 1539 ° C).

The importance of the transformation of metallurgy of inconel steel products at this stage cannot be overestimated. This conversion allows a wide range of microstructures to be achieved through controlled heat treatment. Essentially it is related to microstructure and mechanical properties, therefore, inconel steel products can get a very large range of strength, toughness, etc. The conventional production of inconel steel with 100 MPa and more than 1 GPA has a strong competitive strength. Therefore, the primary concern is the knowledge of the relative stability of the bcc and fcc structures of iron inconel steel.

Physical properties

Density 7.99g / CC

Mechanical behavior

Hardness Tester, Rockwell B 79

Tensile strength, limit 558 MPa

Tensile strength, yield 290 MPa 0.2% YS

Elongation at break 50% 2 inches

Modulus of elasticity 193 GPA Tension

Elasticiteitsmodulus 77 GPA-torsie

Thermische prestatie

Coëfficiënt van thermische uitzetting, lineair 20 ° C 16μm / m- ° C 0 tot 100 ℃

Coëfficiënt van thermische uitzetting, lineair 20 ° C 19,9 μm / m- ° C 871 ° C

Warmtecapaciteit 0,5 J / g- ° C 0 ℃? 100 ℃

Warmtegeleidingsvermogen 16,2 W / mK bij 100 ° C

Warmtegeleidingsvermogen 21,4 W / mK bij 500 ° C

Elektrische prestaties

Weerstand, 7,40E-05 ohm cm

Magenetische penetratie Max 1,02 H = 200 Oersted, gegloeid

Verwerkingsprestaties

Smelttemperatuur 1371 ° C tot 1399 ° C